Introduction

- About P&A Corp.

-

- Established in 1998 in Seoul, Korea as joint invested with Hield Bros., UK.

- Paid Capital: U$2,200,000.

- Export Amount in annual average: U$ 60 million.

- 1st overseas branch in China was opened in 2010

- The Sales Division is composed with Sales Engineers who majored in Metal, Chemistry, Machinery, etc in University.

- CEO

-

- H.S. Kim (1998 - 2020)

- Julie Kim & S.Y. Choi (2020 ~ present)

- Award

-

- Awarded by President of Korea for the excellent performance for export in 2006

CEO Message

We at P&A Corporation are dedicated to "PARTNER FOR HOME APPLIANCE MANUFACTURING"

We have organized ourselves as a compact and lean company so as to maximize our business efficiency. We have always placed our worldwide customers’ satisfaction at the heart of everything we do. We have accumulated significant expertise and technical know-how during the last decade and have specialized departments for parts (components) and raw materials.

We are proud to introduce ourselves as a respected Member of the Korea International Trade Association. Due to our exceptional business performance and enormous contribution in the field of export we received awards by the Korean Government in the years of 1999, 2000, 2004, 2006 and 2008. Notably, in 2008, the President of Korea awarded us a special achievement medal.

If you are looking for a world-renowned Korean company, which displays a high degree of business integrity and loyalty, and a company that demonstrates competence in many business fields, please come and join our worldwide business partners and customers.

Thank you for your time and attention.

Julie Kim & S.Y. Choi

P&A Corporation

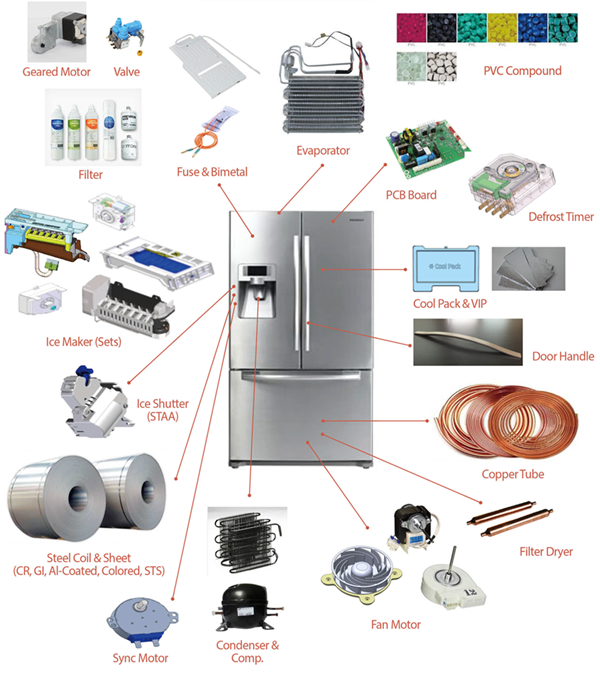

Product Application

Steel

- 1.

- Cold Rolled Steel

(Commercial & Enameling)

- 2.

- Hot Dip Galvanized Steel

- 3.

- Hot Dip AL-Coasted Steel

- 4.

- Colored Steel

- 5.

- Stainless Steel

Components

Compressor

| Product | Reciprocating | Rotary | Scroll | Mini Rotary |

|---|---|---|---|---|

| Image |  |

|

|

|

| Frame | 6 | 5 | 2 | 1 |

| Capacity[Btu/Hr] | 200~1,100 | 3K~65K | 40~160K | 90~390(LBP) 380~1,520(HBP) |

| Factory | Korea, China | China | China | China |

| Production Capacity[M] | 19(11.5/7.5) | 8 | 0.2 | 0.3 |

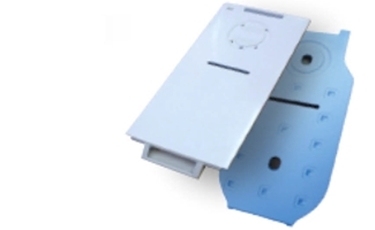

PCB Board & Ice Maker

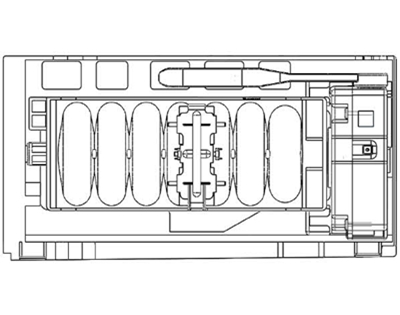

Combi · c-4

Specification

- Power : AC220V/, 50/60Hz

- 5 Sensor (Ref, Fre, Ref Eva, Fre Eva, Amb)

- PCB Size : 110*140(FR-4)

- 2 Door Lamp(Ref : LED Lamp, Fre : LED Lamp)

- 3 Door Swich(Ref, Fre, Bar door)

- 2 Evaporator Type

- 3 Fan(Ref Eva, Fre Eva, Con)

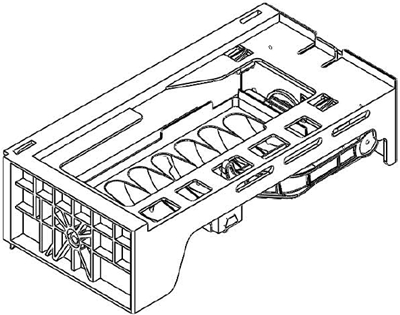

Combi & Ice Maker · C-5

Specification

- Power : AC220V, 50/60Hz

- 6 Sensor(Ref, Fre, Ref Eva, Fre Eva, Dis, Amb)

- PCB Size : 197*148(FR-4)

- ICE Maker (Automatic Type)

- ICE Cube & Crucher

- 3 Door Lamp (Ref, Fre, Bar : LED Lamp)

- 3 Door Switch(Ref, Fre, Bar)

- 3 Fan(Ref Eva, Fre Eva, Con)

- Water Dispensor · 2Vaporator Type · Flux Sensor

Combi & Ice Maker · C-6

Specification

- Power : AC220V, 50/60Hz

- 1 Damper (Electronic Type)

- 4 Seonsor (Ref, Fre, Fre Eva, Amb)

- PCB Size : 111*141(FR-4)

- 2 Door Lamp (Ref, Fre, Fre Eva, Amb)

- 2 Door Switch(Ref, Fre)

- 3 Fan(Ref Eva, Fre Eva, Con)

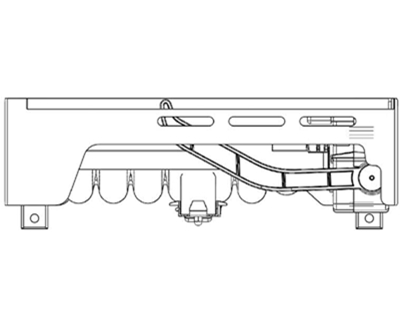

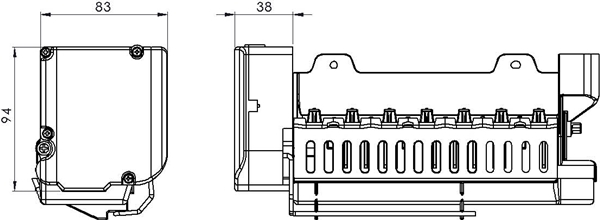

Ice Maker (Twist Type / NTGN)

| SPEC | Comarative Advantage against Other Competitors | Remark | |

|---|---|---|---|

| POsitioning Advangage | cw&ccw Direction is Available, for which user can design any lay-out of Ice-Making unit according to the location of actuator | ||

| Strong Point & Competitiveness | Noise | Relatively Low Noise | Under 75dB |

| Size | Relatively Compact size | 103 X 62 X 53(Drive Unit) | |

| Cold Resistance | It can be Used On Extremely Low Temperature | ||

| Rating | DC 12V | ||

| Output Torque | 400N-CM | ||

| Specification | DC 12V Brush Motor | ||

| Built in ice detecting switch | |||

| Detecting ice Lever in upper and Lower Direction of ice Detecting Operation | |||

| Plastic Tray which Can Detect Ices in Clockwise Direction | |||

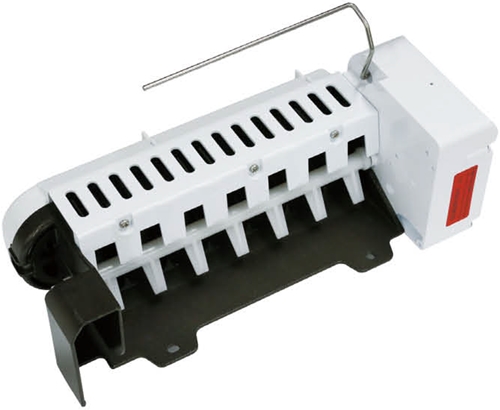

Ice Maker (Heating Type / Full Automatic Type / SZAD)

| SPEC | VALUE |

|---|---|

| Motor | DC 12V Stpping 333pps |

| Heater | 115V AC 130W |

| Thermal Protector | 70℃ |

| RPM(rev/min) | 0.8 ± 0.1min |

| Torque | 4kgfcm ↑ |

| Tray | Aluminum de-casting |

| Rotation | Ejector CW, CCW Possible to control forward and reverse direction |

| Switch | Built in Ice detecting swi |

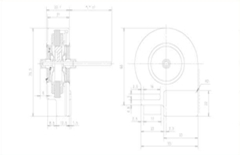

BLDC Motor

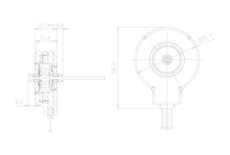

DRⅠ RESIN TYPE BLDC FAN MOTOR FOR SIDE BY SIDE REFRIGERATOR MOTOR

| MOTOR | DRAWING | CLASS | SPECIFICATION |

|---|---|---|---|

|

|

Rated Voltage | DC 12 Y |

| Speed Control | Voltage Control | ||

| Rated Power | 1.3 ~ 1.9 W | ||

| Rated RPM | 1,500 ~ 2,750 RPM | ||

| Efficiency | 45 % |

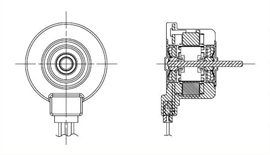

DRⅡ RESIN TYPE BLDC FAN MOTOR FOR SIDE BY SIDE REFRIGERATOR MOTOR

| MOTOR | DRAWING | CLASS | SPECIFICATION |

|---|---|---|---|

|

|

Input Voltage | DC 12 V |

| Rated Power | 2.0 W | ||

| Rated Speed | 1130 RPM | ||

| Rated Torque | 5.5 mNm | ||

| No-Load Speed | 1750 RPM | ||

| Efficiency | 40 % |

DRⅢ BLDC RESIN TYPE MOTOR FOR REFRIGERATOR (SC-PJT) REFRIGERATOR MOTOR

| MOTOR | DRAWING | CLASS | SPECIFICATION |

|---|---|---|---|

|

|

Rated Voltage | 12 V |

| Speed Control | Voltage Control | ||

| Rated Power | 1.4 ~ 1.62 W | ||

| Rated RPM | 1,000 ~ 2,500 RPM | ||

| Efficiency | 45 % |

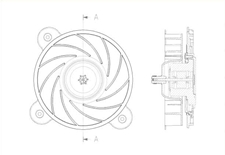

SC-E SC-PJT EVAPOATOR FAN UNIT ASSY REFRIGERATOR MOTOR

| MOTOR | DRAWING | CLASS | SPECIFICATION |

|---|---|---|---|

|

|

Input Voltage | DC 12 V |

| Rated Power | 2.50 W | ||

| Rated Speed | 1870 RPM | ||

| Rated Torque | 6.5 mNm | ||

| No-Load Speed | 2935 RPM | ||

| Efficiency | 45 % |

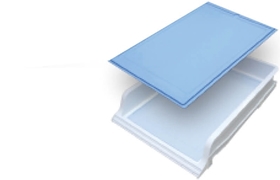

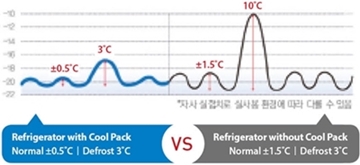

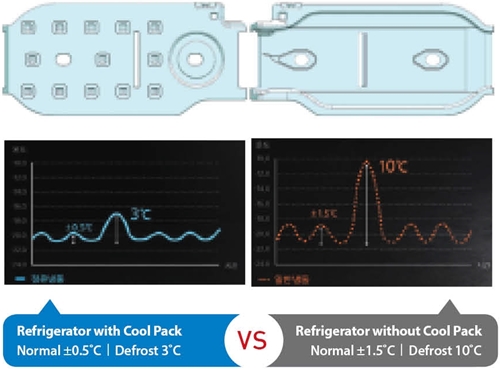

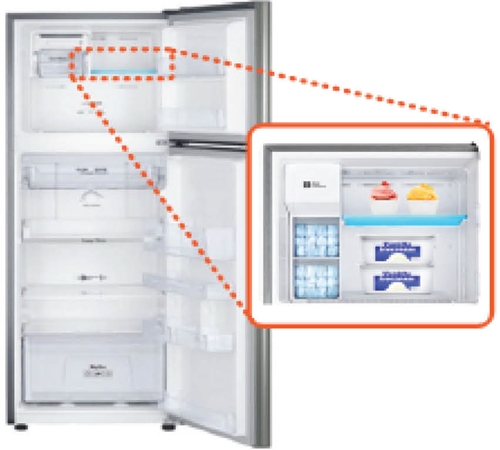

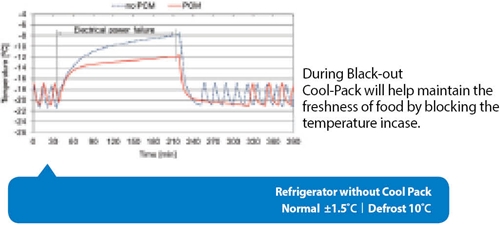

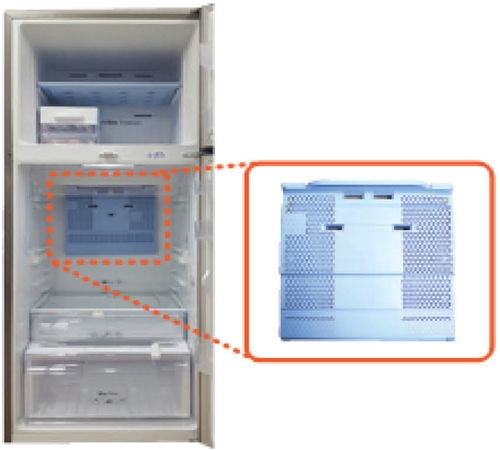

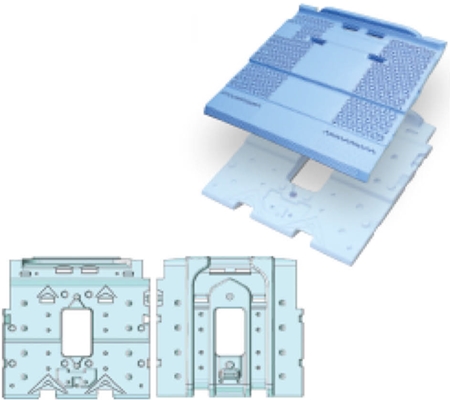

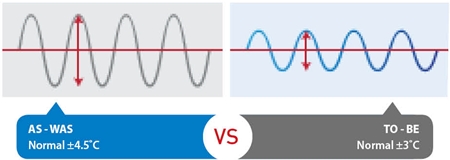

Cool Pack

- Shelf Ice Pack, 800-900ℓ

- For drawer

- Reducing temp. variation (maintain fixed temp.)

- Prevent food to bad in outage

- Maintain freshness with a fine tech

- Technical realization with strtching the fine temp. tech from fridge to freezer

- Serving freshness inside freezer

- Duct Ice Pack, 800-900ℓ

- Chilled air duct for SBS type refrigerator

- Reducing temp. variation (maintain fixed temp.)

- Prevent food to bad in outage

- Maintain freshness with a fine tech

- Shelf Ice Pack, 220-250ℓ

- Shelf Cool pack

- Reducing temp. variation (maintain fixed temp.)

- Main freshness with prevent tamp. rising in defrosting time

- Maintain in chilly condition inside freezer (lasting long time at -11℃ in outage)

- Prevent food bad in outage suppress rising inside freezer

- Duct Ice Pack, 200-250ℓ

- Chilled air duct for TMF type refrigerator

- Reducing temp. variation (maintain fixed temp.)

- Prevent food to bad in outage

Chemical

- Soft PVC Compound

- Rigid PVC Compound

- ABS

- Cyclopentane

- Polyol

- MDI

1. Soft PVC Compound

| Product | G Series | SG Series | |||||

|---|---|---|---|---|---|---|---|

| Test items | Test method (ASTM) |

Unit | 105 | 107 | 112 | 101 | 103 |

| 1. Specific gravity | D792 | - | 1.22 | 1.24 | 1.26 | 1.26 | 1.26 |

| 2. Hardness | D2240 | ShoreA | 61 | 67 | 70 | 67 | 68 |

| 3. Tensile Strength | D638 | kg/㎠ | 100 | 145 | 150 | 120 | 140 |

| 4. Elongation | D638 | % | 290 | 330 | 355 | 290 | 330 |

| 5. Birittleness Temperature | D746 | ℃ | -35 | -28 | -28 | -32 | -34 |

2. Rigid PVC Compound

| Product | PR Series | SH Series | |||||

|---|---|---|---|---|---|---|---|

| Test items | Test method (ASTM) |

Unit | 123 | 130 | 151R | 131R | 130 |

| 1. Specific gravity | D732 | - | 1.43 | 1.44 | 1.48 | 1.49 | 1.27 |

| 2. Hardness | D2240 | Shore D | 80 | 76 | 80 | 82 | 72 |

| Shore A | - | - | - | - | 68 | ||

| 3. Tensile Strength | D638 | kg/㎠ | 450 | 440 | 465 | 470 | 130 |

| 4. Elongation | D638 | % | 130 | 95 | 50 | 70 | 310 |

| 5. Flexural Strength | D790 | kg/㎠ | 750 | 710 | 760 | 860 | 770 |

| 6. Flexural Modulus | D790 | kg/㎠ | 32,900 | 30,500 | 34,500 | 36,100 | - |

| 7. Izod Impact Strength | D256 | kg, cm/cm | 10 | 90 | 10 | 5 | - |

| 8. V.S.P. (1kg load) | D1525 | ℃ | 92 | 90 | 90 | 89 | - |